The Key Benefits of Using Pump Skids for Various Industrial Applications

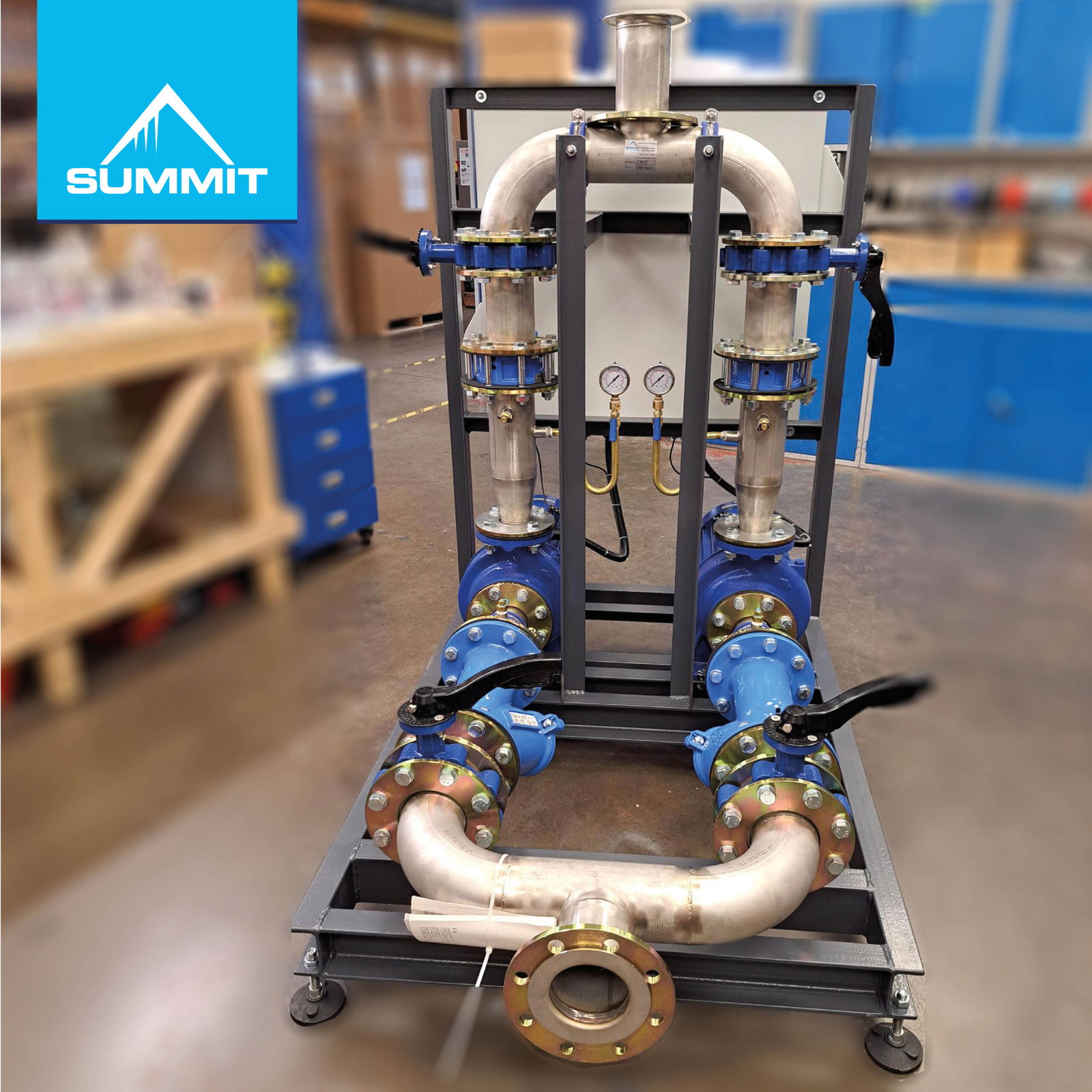

In the realm of industrial applications, efficient fluid transfer and pressure management are crucial for maintaining smooth and uninterrupted operations. Pump skids, which are pre-assembled units comprising pumps, control systems, and auxiliary equipment mounted on a robust skid or frame, offer a host of benefits that make them an ideal solution for various industries. From reducing operational costs to optimising space usage, pump skids provide numerous advantages that enhance both performance and reliability. Learn more below.

1. Cost Efficiency

2. Space Optimisation

3. Enhanced Reliability and Redundancy

4. Simplified Maintenance and Operations

5. Flexibility and Customisation

6. Streamlined Installation and Integration

One of the primary benefits of using pump skids is the ability to closely match the equipment to the specific requirements of the application. By selecting a pump skid that is tailored to the exact flow rates and pressure needs, companies can avoid the pitfalls of using an over-specified system. This precision not only reduces the initial investment cost but also leads to significant savings in operational costs over time. By preventing energy waste and optimising pump performance, pump skids contribute to lower energy bills and reduced maintenance expenses. Industrial environments often face space constraints, making it essential to use equipment that occupies minimal space while still delivering high performance. Pump skids are designed with a compact footprint, with each skid tailored to the size of the pipe model it accommodates. This efficient use of space allows facilities to maximise their layout, making room for other essential equipment and operations. The ability to house all necessary components, including pumps, controls, and piping, on a single skid further simplifies installation and minimises the need for extensive infrastructure modifications. For industries where continuous operation is critical, such as oil and gas, chemical processing, and water treatment, pump skids offer enhanced reliability through their dual pump configurations. The dual pump setup, designed for run-standby operation, ensures that processes can continue without interruption. In the event that one pump requires maintenance—such as cleaning or replacing a strainer—or if a pump experiences a malfunction, the second pump seamlessly takes over. This redundancy minimises downtime and prevents costly disruptions, ensuring that industrial processes remain operational around the clock. Pump skids are engineered to facilitate easy maintenance and operational efficiency. Features such as pressure gauges, strainers, and non-return valves are incorporated to provide real-time monitoring and protection of the system. For example, strainers protect pumps from debris and contaminants, extending the lifespan of the equipment and reducing the frequency of repairs. Additionally, the modular nature of pump skids allows for straightforward access to components, making routine maintenance tasks simpler and faster. This ease of maintenance translates to lower labour costs and increased uptime. Every industrial application has unique requirements, and pump skids offer the flexibility to be customised accordingly. Summit Process Cooling provides a range of standard options and optional extras that allow customers to tailor their pump skids to meet specific needs. Options include single or dual inverters for precise speed control, pressure transducers for advanced monitoring, and snow hoods for outdoor installations with IP55 protection. This level of customisation ensures that each pump skid is optimised for its intended use, enhancing overall system efficiency and effectiveness. By pre-assembling all necessary components onto a single skid, pump skids streamline the installation process. This reduces the time and complexity associated with on-site assembly and integration, allowing facilities to bring new systems online more quickly. The plug-and-play nature of pump skids also facilitates easy integration with existing systems, minimising disruptions to ongoing operations and simplifying the commissioning process. Pump skids offer a host of benefits that make them an invaluable asset in a wide range of industrial applications. From cost savings and space optimisation to enhanced reliability and ease of maintenance, pump skids provide the flexibility and efficiency needed to meet the demands of modern industrial operations. By choosing customisable and high-performance pump skids from Summit Process Cooling, industries can ensure that their fluid handling and pressure management needs are met with precision and reliability, leading to improved operational efficiency and reduced total cost of ownership. today at to discuss further with our team of cooling experts

Learn more about our Pump Skids