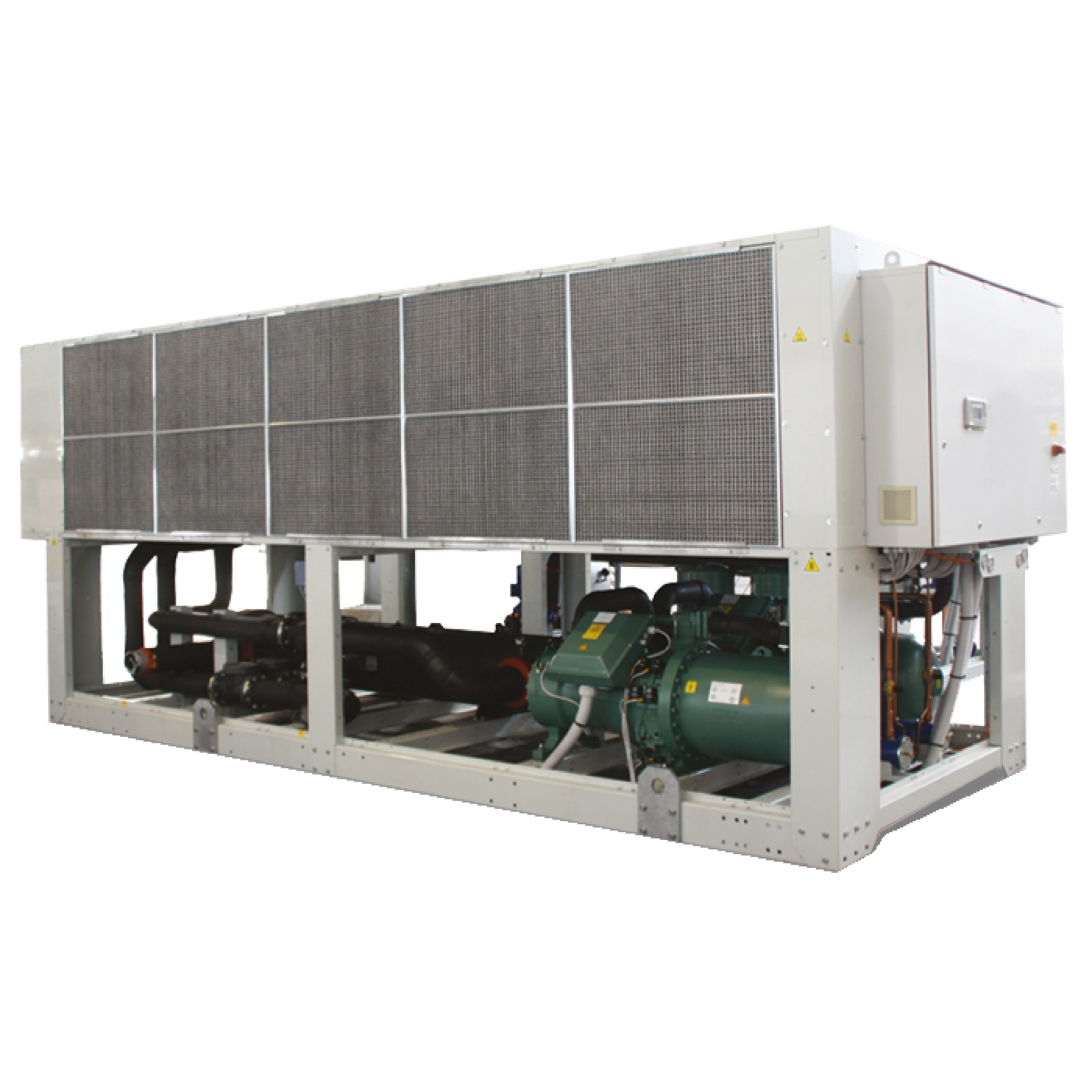

Free Cooling Chillers are designed to dramatically reduce energy consumption by harnessing ambient air to cool process water, allowing partial or complete shutdown of the refrigerant circuit in cooler conditions. Available in models up to 1,500 kW, these systems combine traditional chiller technology with an integrated dry cooler and smart controls to optimise performance year-round. Ideal for energy-conscious industries, free cooling chillers lower running costs, extend equipment lifespan, and support sustainable operation without compromising on cooling capacity.

A Free Cooling Chiller is an advanced chiller system with an integrated Free Cooling System. This design combines the reliability and versatility of a traditional chiller, with the benefits of a free cooling operation, offering an optimised solution for cooling needs.

An integrated Free Cooling Chiller operates by harnessing cooler ambient outdoor temperatures to cool process fluid, thus reducing energy consumption and operational costs. This mechanism typically involves an air-to-fluid heat exchanger and fans that pull in outside air over the heat exchanger. During colder months, the system transfers heat from the warm process fluid to the cooler ambient air before it reaches the chiller. This process significantly decreases the workload of the chiller, leading to energy savings and a reduction in carbon footprint.

Whether integrated into new industrial environments or retrofitted into existing ones, Free Cooling Chillers offer a cost-effective operational solution that balances efficiency, cost-savings, and environmental responsibility. To find out more, visit our recent article on Free Coolers.

Free Cooling Chillers are used across a range of applications, including:

Free Cooling Chillers offer a multitude of advantages for businesses seeking efficient and cost-effective cooling solutions. Thanks to their ability to leverage ambient air to cool liquids, they can significantly reduce your energy consumption and utility costs. This decreased reliance on mechanical cooling extends the lifespan of the chiller, which reduces maintenance requirements and enhances system reliability by minimising strain.

With the ability to switch automatically between free cooling and mechanical cooling modes, these units provide flexible operation tailored to external temperature conditions. Environmentally conscious businesses can also benefit from the reduced carbon footprint associated with lower energy usage.

While initial costs may be higher than traditional chillers, the combined energy and maintenance savings typically result in a quick return on investment, usually within 6 to 12 months. In certain high-demand situations, free cooling systems can even offer increased cooling capacity. Therefore, integrating or retrofitting free cooling systems into industrial processes can drastically improve a business’s productivity, efficiency, and sustainability.

The primary difference between a cooler and a chiller lies in their mechanism and the costs involved. A cooler, like our Free Cooling System, utilises ambient air drawn over a heat exchanger by fans to cool fluids, thus significantly reducing energy costs.

Conversely, a chiller employs mechanical refrigeration techniques to cool process fluid. While chillers can provide more intensive cooling, they typically come with higher operating costs due to their complex refrigeration process. Thus, choosing between a cooler and a chiller boils down to your specific cooling needs and budget considerations – if you need help choosing, get in touch with our expert team today.

Chillers traditionally consume significant electricity, mainly due to their operation principle. However, Free Cooling Chillers are designed to reduce this energy usage significantly. These systems intelligently utilise ambient air temperature to cool the system, reducing the need for mechanical cooling.

Therefore, while conventional chillers may use a lot of electricity, the implementation of Free Cooling Chillers can lead to considerable energy savings, making them a cost-effective and eco-friendly choice.

We provide a wide range of cooling capacities, designed to cater to varying industrial and application-specific needs. These capacities have been engineered to guarantee the best possible performance and maximise energy efficiency.

Regardless of your cooling requirements, you can find a Free Cooling Chiller that fits your needs perfectly, thereby ensuring optimal operational outcomes and substantial energy savings. Get in touch to find out more.

We offer custom-tailored support and assistance for technical difficulties, especially during system failures. Our mission is to ensure uninterrupted operation and boost efficiency for all of our customer’s cooling systems. Do note that the level of service provided depends on the maintenance contract you have with us.

This service is not limited to our own systems; we can deliver a similar service on any machinery.

We understand the criticality of rectifying any issues with your cooling system. That’s why we offer rapid and efficient repair services. Our engineers can be dispatched to your location promptly, capable of replacing parts and resolving any technical issues – often during the initial visit.

Are you seeking a temporary solution for industrial cooling? Summit Process Cooling is here to offer chillers on rent, to address temporary malfunction coverage or seasonal equipment that isn’t required for 12 months of the year.

Regardless of your specific needs, don’t hesitate to reach out for assistance in selecting a system that aligns with your requirements.